Elina and were getting antsy. We had now been at WAIS 9 days and hadn’t gotten to any of our planned sites. It’s nice that we got two extra site visits in, but we wanted to start checking sites off of our original to-do list. On 7 January, we finally got that opportunity, and it was even to visit our highest priority site, Bear Peninsula!

This site was highest priority because it is on the coast (far and usually bad weather), and we needed to replace a fraying guy wire. We also wanted to install a new Taylor high wind system, as the environment there is pretty rough on RM Young wind monitors.

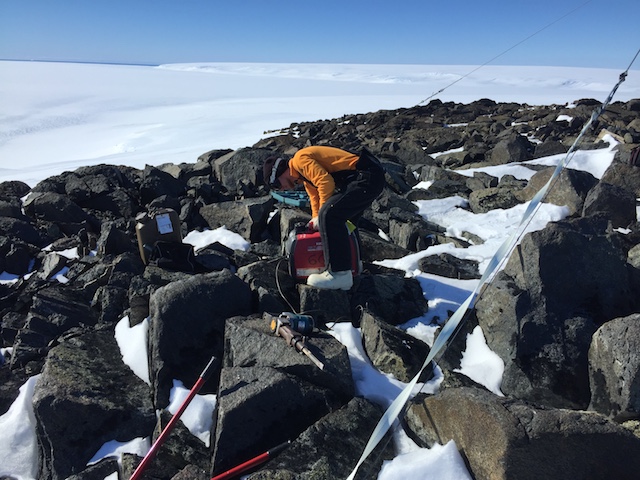

Given all of this work we needed to do there, we had a lot of cargo to bring with us, including a generator, demolition hammer, and jerry can with fuel so we could chip out the large rock that has been fraying one of the guy wires. Fortunately, a couple people from camp, Andy Boyd (mountaineer) and Aurora Roth (PASSCAL), came with us and helped carry our gear from the plane to the site. The terrain makes it a difficult hike and carry cargo from the plane to the site, as we would need to walk up a hill that, for the first half, is snow and ice. The second half, where the site is located, is very rocky and uneven. Having extra hands was a huge help. It took us about 25 minutes to walk from the plane to our AWS.

Bear Peninsula (this was taken at the end of the visit), showing the snowy/icy hill that leads to the rocky top of the hill. Our site is not pictured but is on the other side of the hill.

It was a very nice day, with temperatures around 25 F and light winds, which did pick up a little bit during the visit but then decreased again. Everyone helped carry cargo from the plane to our site, then only Elina and I stayed to start the work as everyone else went back to the plane and the seismic site that Aurora had come to service. The first thing Elina and I did was chip out part of the large rock that was fraying the guy wire.

We used the demolition hammer as a chisel, but instead of needing to use a hammer to pound every strike, the demolition hammer does that automatically for us and at a much faster rate. It’s great! We were sure to wear safety glasses and cover our faces with a balaclava or neck gaiter, as lots of small bits of rock would fly up during demo-hammering.

Me starting the generator. The demolition hammer is in the foreground, with the chisel piece attached.

It was very difficult to chip off sufficient rock (who knew??). One has to push pretty hard, straight into the rock, to make any progress. If you were at a poor angle, the hammer would just slide off the rock face. Once you started to make a dent/hole in the rock, it got easier to keep the hammer in the same spot. We essentially using the demo hammer to drill holes into the rock to weaken it, then chips of it would fall off. The whole process took about 30 minutes, but eventually we did it!

Next, we needed to replace the bad guy with a new one (and remove the cargo strap that was acting as a fail-safe in case the guy wire snapped). At this point, everyone else had come back from the plane/seismic site to help and/or observe our work. Andy and I worked on installing the new guy wire while Elina worked on replacing some equipment on the tower and retrieving the CR1000 program.

We wanted to install new Taylor high wind system to replace the existing wind monitor which had broken a couple years ago (at least). Unfortunately, there was a plug mismatch between the cable plug and the enclosure, so we couldn’t install it. We removed the broken wind monitor anyways, as it wasn’t serving any purpose sitting on the tower. We did some other servicing at the site like swapping some radiation shields for the temperature and relative humidity sensors.

Soon after, everyone started to ferry gear back to the plane, and just like that we were done at Bear Peninsula.

Cheers! -Dave